Travel I-75

Project Highlights - Tunnel Edition

April 2024 Update - The I-75 Modernization tunnel drainage system is now in place and ready for the next rainstorm. This important piece of the project was built to help alleviate future flooding on the I-75 freeway from 8 Mile Road to 12 Mile Road. We are grateful for the opportunity to support the community with the addition of this drainage tunnel and thank everyone for their patience as it was constructed. We have resources on our project website to learn more about how the tunnel was built and how stormwater flows into the tunnel once it reaches the roadway.

June 2023 Update - the tunnel boring machine (TBM) has reached the shaft at Meyers Avenue (the southern endpoint). This milestone is another great accomplishment for the project and all those working to complete this drainage system.

Crews will begin removing the TBM from the Meyers Avenue Shaft. Once the TBM and its equipment are removed, crews will begin completing the drop shaft work south of I-696 and finalizing the tunnel drainage system so it can begin accepting water. This work is expected to continue through the end of 2023.

See video below for a peak at the breakthrough.

October 2022 Update - the Tunnel Boring Machine (TBM) has reached the pump station just north of 12 Mile Road (the northern end point). This milestone is a great accomplishment for the project and all those working to complete this drainage system.

The TBM was removed from the 12 Mile Road pump station and will be relaunched from the I-696 shaft construction site, proceeding south to a shaft site located near Meyers Avenue (see tunnel sequencing map). The relaunch process is expected to take a few months and the TBM will continue working into the summer of 2023. Once the TBM has completed mining operations, it will be removed from the ground allowing crews to complete drop shaft work and finalize the tunnel drainage system. Concurrent with the tunnel mining, crews will complete the pump station north of 12 Mile Road in preparation to accept the tunnel drainage.

July 2022 Update - Thanks to the hard work and dedication of the team we are happy to announce tunneling operations have resumed. This spring, crews were able to access the original Tunnel Boring Machine (TBM) via the repair shaft and removed it. The contracting crews then lowered in a new TBM (utilizing some parts from the original) allowing them to resume tunneling approximately 100 feet underground.

The TBM is now mining northward on its path to the 12 Mile Road pump station site. The TBM will then be removed from the 12 Mile Road pump station shaft, be relocated back to the launch site at the I-696 interchange and begin working its way south to the Meyers Avenue shaft site. After the TBM has completed its job in late 2023, it will be removed from the ground and decommissioned as crews complete pump station and drop shaft work and finalize the tunnel drainage system.

April 2022 Update – Construction of the repair shaft is complete, and repairs to the Tunnel Boring Machine (TBM) are underway with tunneling operations expected to resume early this summer and continue through 2023.

February 2022 Update – A ground settlement event occurred on July 30, 2021, along the northbound I-75 service drive between 11 Mile Road and Gardenia Avenue. The site was stabilized, and the repair phase is underway. Construction of the repair shaft is currently in process and tunnel work is anticipated to continue this spring.

_______________________________________________

Tunnel Videos

| I-75 Modernization Project Tunnel Construction June 2023 |

| Tunnel Excavation has reached the Meyers Avenue Shaft! (June 2023) |

| TBM Breakthrough at 12 Mile Road Pump Station - September 2022 |

| I-696 Tunnel Shaft - February 2020 |

_______________________________________________

What is the “Tunnel”?

The “Tunnel” was a major part of the drainage system improvements that was constructed for I-75 Segment 3. This storage and drainage tunnel system is four-miles long, 14.5-foot diameter and 100 feet underground generally along I-75’s northbound service drive between 8 Mile and 12 Mile Roads.

Why do we need the Tunnel?

|

| Photograph: Michigan State Police boat patrols on I-75 at I-696 in August 2014 |

The previous drainage system is almost 50 years old and was in need of improvements. In the summer of 2014 and in recent years, the Metro Detroit area experienced some of the worst floods on record. The 14.5-foot diameter, 4-mile long drainage tunnel provides storage and conveyance to help avoid future flooding in the depressed portion of the I-75 freeway from 8 Mile Road to 12 Mile Road.

Where is the Tunnel located?

The main tunnel construction site was in the northeast quadrant of the I-75/I-696 interchange and work began in the fall of 2019 to construct a 100-foot-deep shaft. The tunnel boring machine (TBM) launched from this shaft in late-spring 2020 and mined (dug) its way 100 feet underground north from the I-696 interchange to a pump station located just north of 12 Mile Road. The TBM was removed and relaunched from the I-696 construction site south to a shaft site located near Meyers Ave (See map image below).

How was the Tunnel constructed?

|

| Photograph: TBM Cutter and Shield Unit |

|

| Photograph: Front of TBM assembly |

The tunnel for I-75 was constructed with a tunnel boring machine (TBM). A TBM is an automated machine with a rotating cutting wheel with teeth at the front that digs away at the soil while it turns. Miners in the tunnel installed 5-foot long precast concrete wall segments within a shield to protect them. Hydraulic jacks at the back of the TBM pushed against the ends of the wall segments after they were installed to force the cutting wheel into the soil and move the tunnel forward. Behind the shield was a 300-foot long assembly of support equipment, including electrical, mechanical and ventilation equipment. A small locomotive on rail tracks travelled up to 2 miles between the TBM and the I-696 shaft with boxes to haul out excavated soil and flatbed cars to bring in the concrete wall segments.

How does the Tunnel work?

|

| Photograph: Aerial view of Tunnel Construction Shaft at the I-75/ I-696 Interchange |

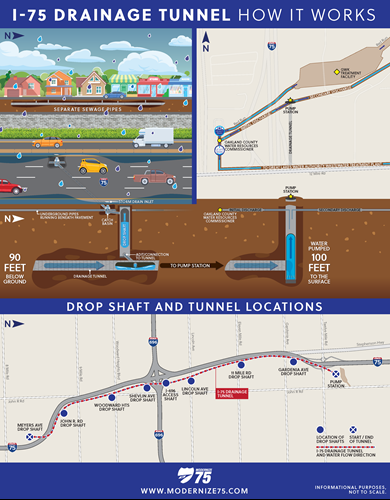

Storm water is collected from the I-75 freeway and service drives in a network of pipes that direct flows into seven “drop shafts” (large pipes). These shafts connect to the tunnel below, where the storm water then flows north to a new pump station just northeast of the I-75 and 12 Mile Road interchange. The pump station lifts the water nearly 100-ft and discharges it into the Oakland County Water Resources Commissioner (OCWRC) Retention Treatment Facility.

Infographic to show what happens when rain hits the roadway and makes its way to and through the drainage tunnel.

When will the Tunnel and pump station be completed?

The tunnel work began in the Fall of 2019, experienced a delay in 2021, and continued into late 2023. The TBM began working north from the I-696 interchange to the 12 Mile Road pump station. The TBM was then removed from the 12 Mile Road pump station and relocated back to the launch site at the I-696 interchange to begin working its way south to the Meyers Avenue shaft site. When it reached the Meyers Avenue shafter site, it was removed from the ground and decommissioned (taken apart) as crews completed pump station and drop shaft work and finalized the tunnel drainage system.

Fun Fact

Historically, a TBM was generally named after a woman as a sign of good luck for the project ahead. Naming digging equipment after women is a tradition that dates to the 1500’s when miners prayed to Saint Barbara to keep them safe underground. Workers looked to Saint Barbara for protection as she is the patron saint for military engineers, miners and others who work underground.

The TBM for this project was named “Eliza” after a community vote through the Oakland Corridor Partners (OCP) website. https://ocp-i75.com/tbm-naming-contest

Eliza Seaman Leggett was chosen as she was an active participant in the Underground Railroad and her Waterford Township home in Oakland County was a stop on the Underground Railroad. Upon the abolition of slavery, Ms. Leggett turned her attention towards the suffrage movement and helped women in need. During the 1870’s she devised, co-founded, and implemented the Young Woman’s Home Association for the young working women of Detroit. She was instrumental in making Belle Isle a public park for the people of Detroit. She also ensured that public drinking fountains and horse watering troughs were placed throughout the City of Detroit.